Brian Miller, Stewart Smith and Helen Bridle*

School of Engineering, University of Edinburgh, 3.17 William Rankine Building, Kings Buildings, Edinburgh, EH9 3JL, UK

Email: h.bridle[at]ed.ac.uk

Why is this useful?

Jie Xu and Daniel Attinger previously described a method to prevent the sagging of high aspect ratio channels during bonding [1]. The method involves careful placement of salt crystals into the channel prior to bonding to create a supporting structure. A limitation of the technique is the depth of channels this method can be used on, which must be within the size range of the salt crystals (~100 μm).

Described here is a method that builds on this technique to allow salt structures to be created with much smaller surface profiles, down to between 25-35 μm maximum heights of profile. This will allow the technique to be applied to shallower channels for devices in which performance is sensitive to channel height, for example, inertial focusing devices (Fig.1) [2,3].

This refined technique also helps to simplify the handling of the devices after preparation; reducing the risk of contamination of equipment as, once they are applied, the salt crystals are adhered to the surface of the device.

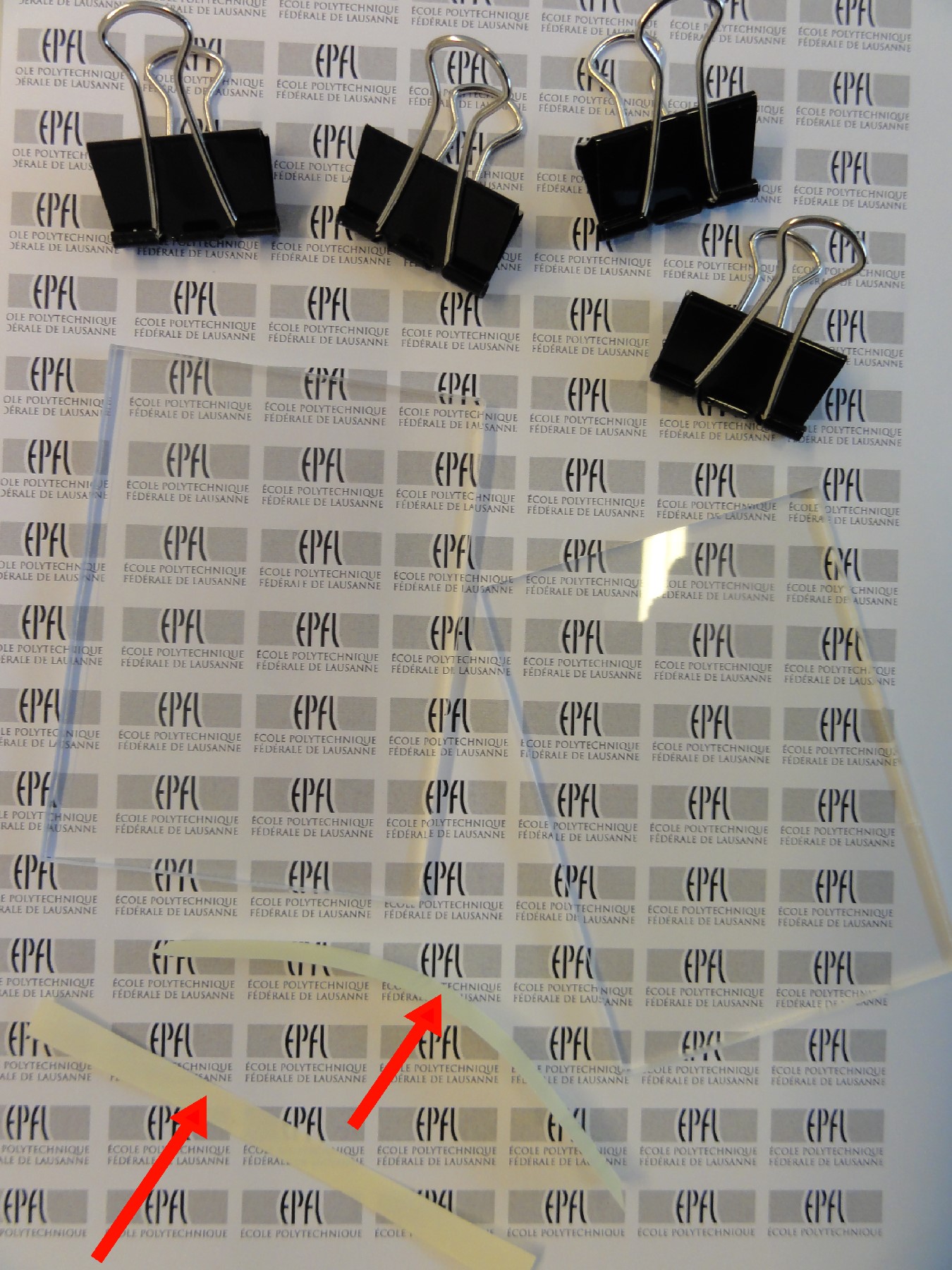

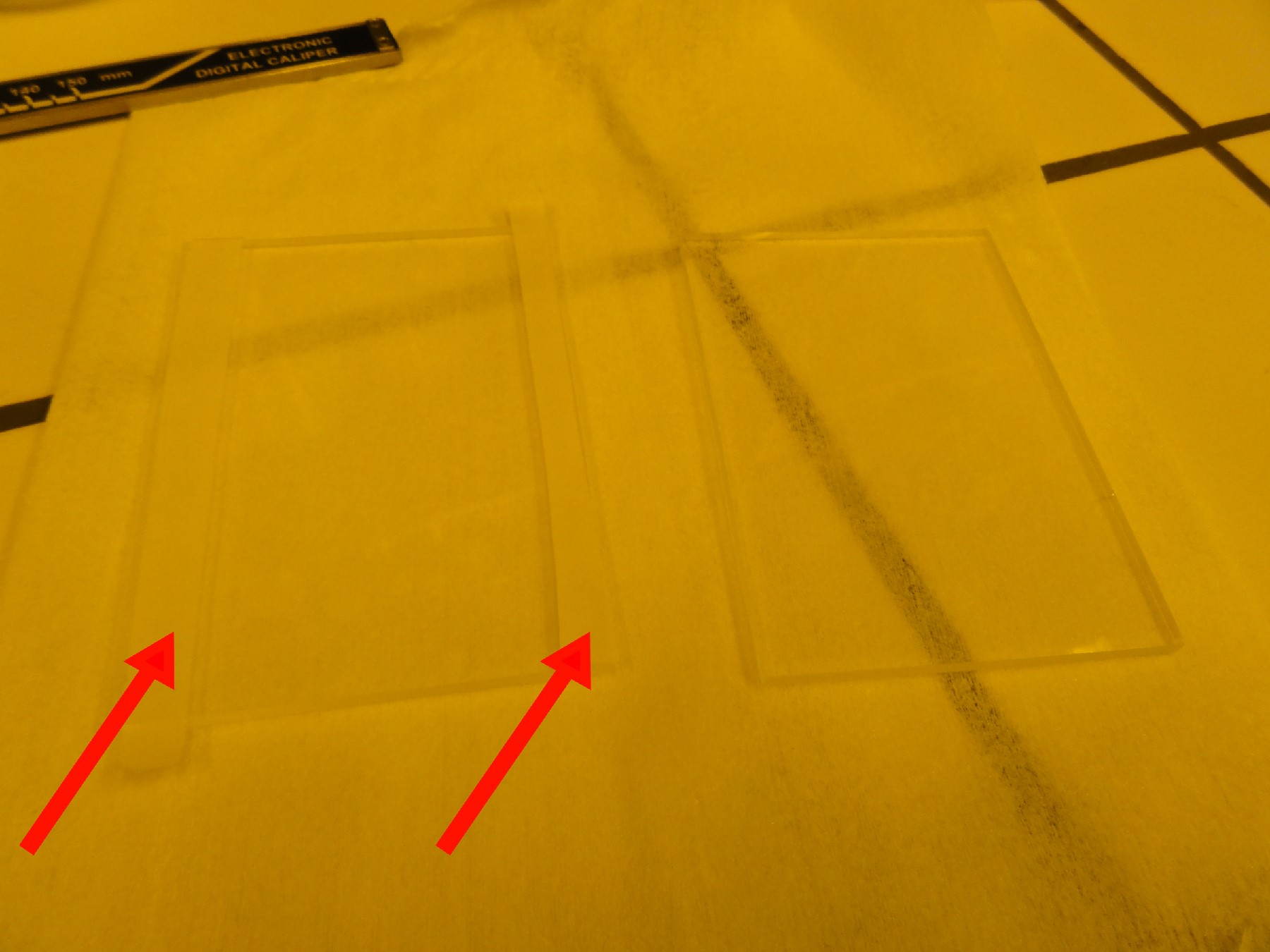

- Figure 1. Inertial focusing device A; with solution applied to high aspect-ratio sections as indicated in pinched-flow segment B and output leg C. Device depth is 30μm (max. aspect ratio 60:1 in PDMS)

What do I need?

- High purity KCl (potassium chloride salt)

- De-ionised (DI) or reverse osmosis (RO) water

- Weighing balances/scales

- Decon 90 surfactant

- Hypodermic needle (thin gauge)

- Magnetic stirrer

- Beaker and syringe

What do I do?

- Prepare a solution of the salt and surfactant by measuring 100ml of DI or RO water into the beaker. Add 1.5g of KCl to the water and stir gently for two minutes. Use the syringe to add 5ml of Decon 90 to the solution and stir very gently for a further two minutes, taking care not to foam the solution. Do not allow the solution to rest for more than a few minutes after stirring.

- Bending the sharp point of the hypodermic needle on your workbench or other hard, clean surface can help to ‘grab’ sufficiently small quantities of solution from the beaker. Use the needle or a similar applicator to carefully apply a small quantity of solution to the high aspect ratio section of your channel (Fig. 2). Only a very small volume is required and it is important to not allow the solution to overflow the channel. Dabbing the needle on a dust/lint-free wipe can help to regulate the amount of solution delivered to the surface of your device. If you accidentally over-apply the solution, clean the device with DI/RO water and IPA, and re-attempt application once it has dried.

- Allow the solution to evaporate at room temperature without assistance of any kind (no added air-flow or heat). An area of crystal formation should form where the solution was applied. The edges of this area tend to grow larger due to the ‘Marangoni effect’. The edge will typically be a maximum of 30-35μm in height, with the centre of the area typically yielding crystal formations between 10 and 25μm tall (as measured on a surface profiler over 4 repetitions), which should suffice to prevent the unintended bonding of the ceiling to the floor of the channel.

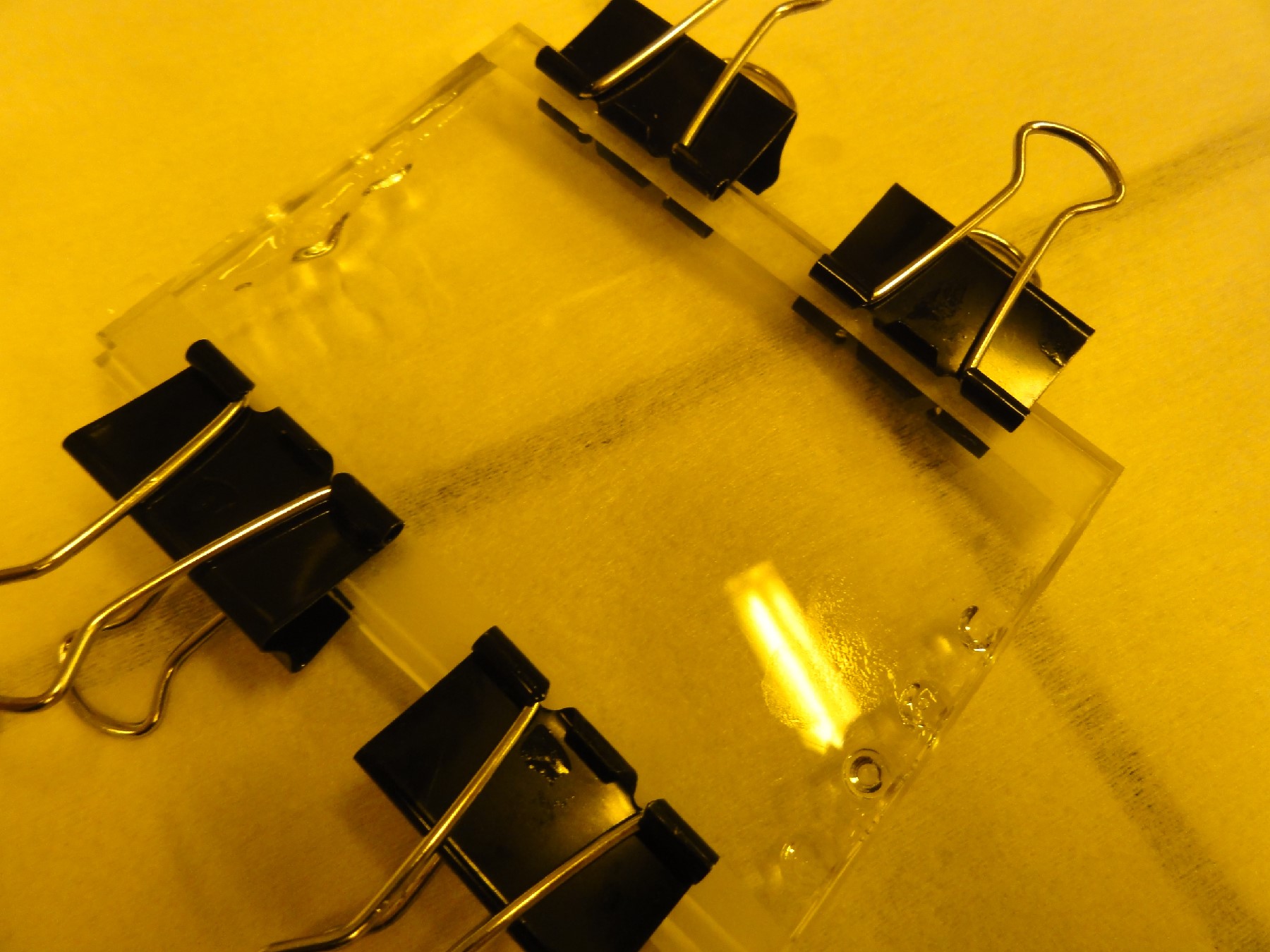

- Bond your device to your substrate layer following your normal bonding procedure (we used oxygen plasma bonding of PDMS to a glass microscope slide in this example).

- Before using the device, run water or buffer through to dissolve away the crystal formations (Fig. 3). The surfactant helps to quickly remove the salt structures and leave the device clean of any remnants.

- Figure 2. Careful application of very small quantities of solution into channels, using a hypodermic needle

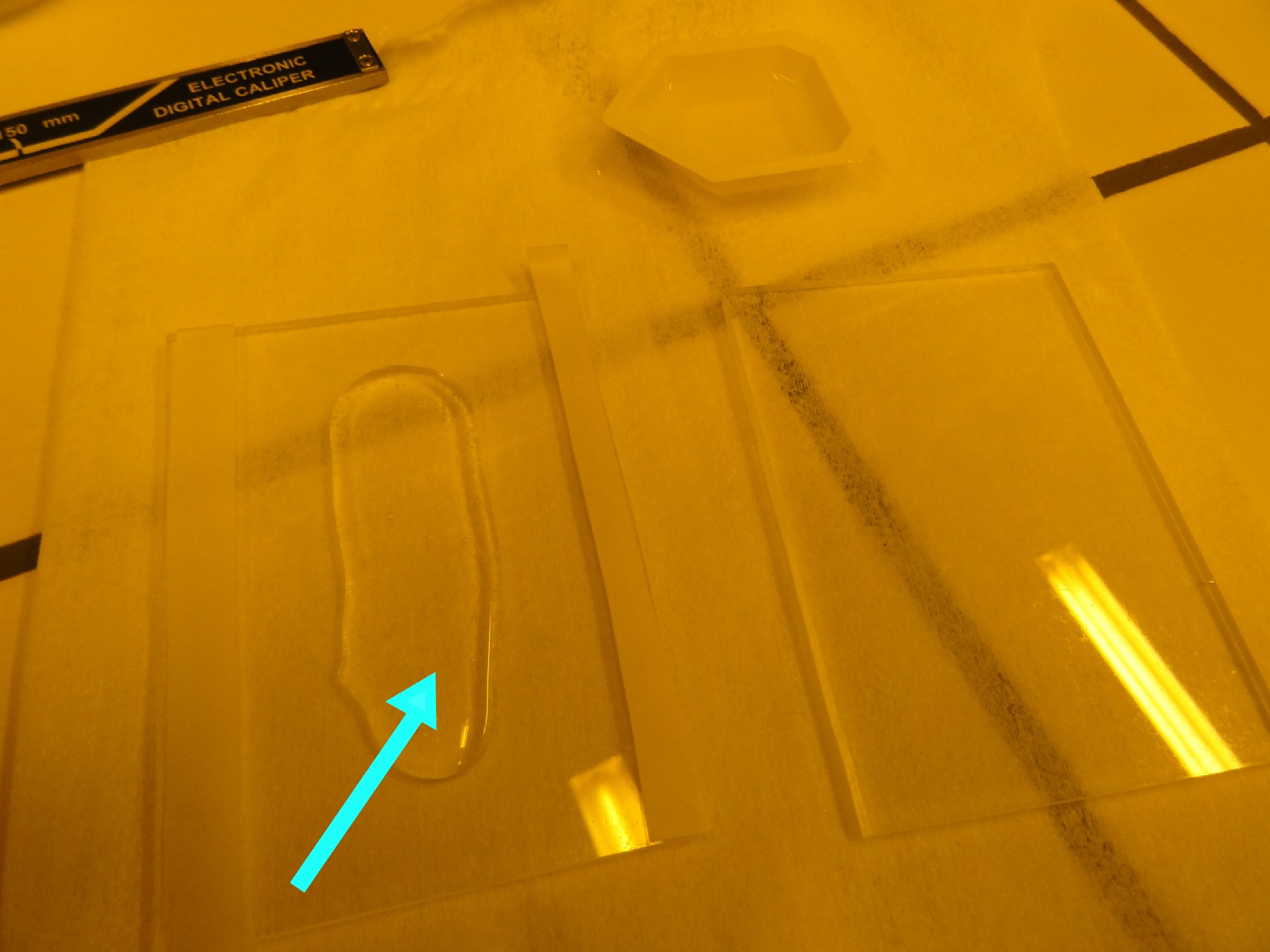

- Figure 3. Top: water salt formations in the support structure before rinsing with DI/RO water. Bottom: the same area after rinsing through, illustrating that practically no residue is left in the device

Notes

- Failure to use the surfactant will result in much larger crystal formations, as the crystal structures nucleate in very few locations and form much deeper structures. It is conjectured that the surfactant suspends the salt ions with a larger interspaced distribution throughout the solution, causing a much more distributed nucleation of the crystals and yielding the lower profile crystal formations.

References

[1] Jie Xu and Daniel Attinger, How to prevent sagging during the bonding or lamination of chips with large aspect ratio chambers, Chips & Tips (Lab on a Chip), 24 July 2009.

[2] D. Di Carlo, D. Irimia, R. G. Tompkins and M. Toner, Continuous inertial focusing, ordering, and separation of particles in microchannels. Proc. Natl. Acad. Sci. U. S. A., 2007, 104, 18892-18897.

[2] D. Di Carlo, J. F. Edd, D. Irimia, R. G. Tompkins and M. Toner, Equilibrium separation and filtration of particles using differential inertial focusing. Anal. Chem., 2008, 80, 2204-2211.