The most chemically and thermally stable metal-organic frameworks (MOFs) yet have been made by a team in the US. The MOFs could surpass zeolites as industrial catalysts.

Natural zeolites are porous alumina-silicate rocks used as catalysts in industrial processes. However, their pore sizes and surface functionalisations are difficult to alter, which limits their performance. MOFs – made by joining up metal oxide clusters with linking organic molecules – have similar structures to zeolites and are therefore of interest as alternatives. Until now, they have not been robust enough to withstand the conditions that zeolites undergo during industrial processes. Traditionally, MOFs have only been stable in temperatures up to 500 degrees Celsius, have low chemical stability and some even fall apart in water.

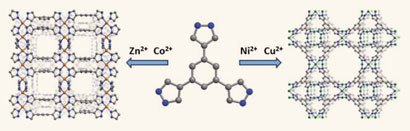

Jeffrey Long from the University of California, Berkeley, and colleagues have made MOFs that can withstand temperatures of 510 degrees Celsius and a pH range of 2 to 14. They made the MOFs by reacting a metal salt, such as nickel chloride or nickel nitrate, with trispyrazolylbenzene. The organic molecules were deprotonated and the functional groups were bound to the metal to create a three-dimensional network.

Find out more by reading the full news story in Chemistry World and downloading Professor Long’s Chemical Science Edge article.

Also of interest:

Modifying MOFs: new chemistry, new materials

Seth M. Cohen, Chem. Sci., 2010, 1, 32-36

Hydrogen storage and carbon dioxide capture in an iron-based sodalite-type metal–organic framework (Fe-BTT) discovered via high-throughput methods

Kenji Sumida, Satoshi Horike, Steven S. Kaye, Zoey R. Herm, Wendy L. Queen, Craig M. Brown, Fernande Grandjean, Gary J. Long, Anne Dailly and Jeffrey R. Long, Chem. Sci., 2010, 1, 184-191