Scientists in China have developed a material that reduces the time required for a skin wound to heal.

A range of research has been conducted into the promising biomedical applications of chitosan, as it can clot blood effectively. Bingan Lu and his colleagues at Lanzhou University have developed a method to combine the benefits of chitosan with graphene, which has been shown to have antibacterial properties.

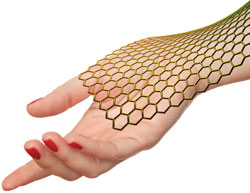

Lu’s team mixed graphene with chitosan-polyvinyl alcohol (PVA) nanofibres using electrospinning (a process in which an electrical charge is applied to draw very fine fibres from the solution). The chitosan nanofibres combined with the graphene, forming thin membranes.

The team applied the membranes to small skin wounds. Lu says that the membranes ‘covered the wounds like a band aid and, usually, one wound only needed one graphene-chitosan-PVA membrane’. They found that after 10 days, the wounds were significantly more healed than those without the membrane.

A membrane formed from chitosan, which clots blood effectively, and graphene, which is antibacterial, speeds up wound healing

Chunhai Fan, an expert in graphene materials at the Chinese Academy of Sciences, says that the work ‘shows a really interesting health application of graphene-based nanomaterials’ and adds that it ‘clearly shows that graphene-based antibacterial materials facilitate wound healing’.

To test the membrane further, Lu’s team used cell cultures to show that graphene is only detrimental to bacterial cells, and animal cells are unaffected. They suggest that this may be due to graphene transferring electrons through cell membranes. Bacterial cells are prevented from replicating by this process, as the electrons can reach the bacterial DNA, destroying it. Animal DNA is protected from the electrons by a second membrane. The team intends to investigate graphene’s antibacterial properties to confirm the mechanism.

Graphene-based composite materials beneficial to wound healing

Bingan Lu, Ting Li, Haitao Zhao, Xiaodong Li, Caitian Gao, Shengxiang Zhang and Erqing Xie

DOI: 10.1039/C2NR11958G

Read the original article at Chemistry World