Christopher N. LaFratta

Department of Chemistry, Tufts University, Medford MA, USA

Why is this useful?

Mixing the base and curing agent of PDMS inevitably incorporates air bubbles into the prepolymer. These bubbles are usually removed after casting by degassing the sample under vacuum. Vacuum degassing works well but requires about 30 minutes or more depending on the vacuum and amount of gas stirred in. The technique described here uses a typical laboratory centrifuge to degas PDMS in two minutes. The centrifuged PDMS will yield a bubble-free solid silicone rubber when cast on a smooth surface.

What do I need?

- SYLGARD 184 silicone elastomer base & curing agent (Dow Corning)

- 2 Centrifuge tubes (15 mL)

- Clay Adams II compact centrifuge (3200 rpm or 1315 × g relative centrifugal force)

How do I do it?

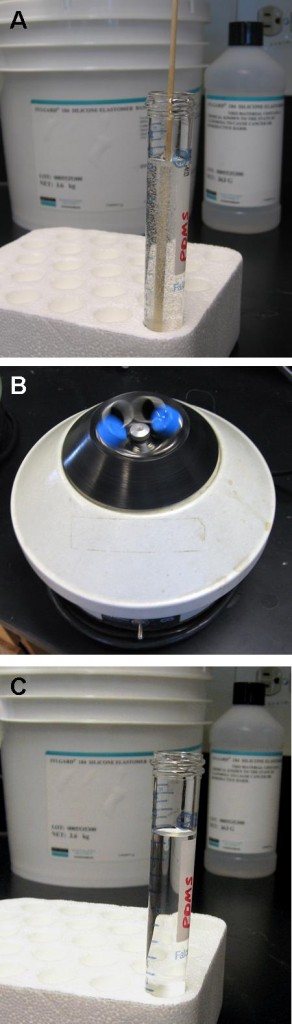

- Weigh the PDMS base and curing agent (10:1) in a disposable centrifuge tube.

- Mix base and curing agent together with a wooden stick.

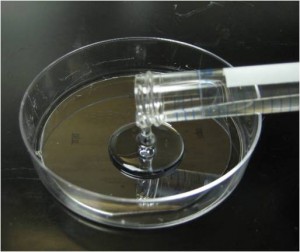

- Balance centrifuge with 2nd tube containing comparable amount of PDMS or water. Place in centrifuge for 2 min.

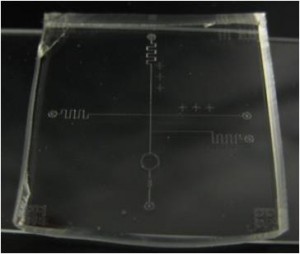

- Cast centrifuged PDMS onto patterned wafer.

- Oven cure at 75°C for 1 h.

What else should I know?

If the PDMS is cast over high aspect ratio features, such as tall SU-8 photoresist lines, air bubbles may get folded in as the liquid PDMS flows over crevices. These small isolated bubbles can usually be degassed under vacuum in about one minute.

References

[1] C. N. LaFratta, T. Baldacchini, R. A. Farrer, J.T. Fourkas, M. C. Teich, B. E. A. Saleh, M. J. Naughton J. Phys. Chem. B, 2004, 108, 11256-11258.